Our Factory: Innovation, Scale, and Global Recognition

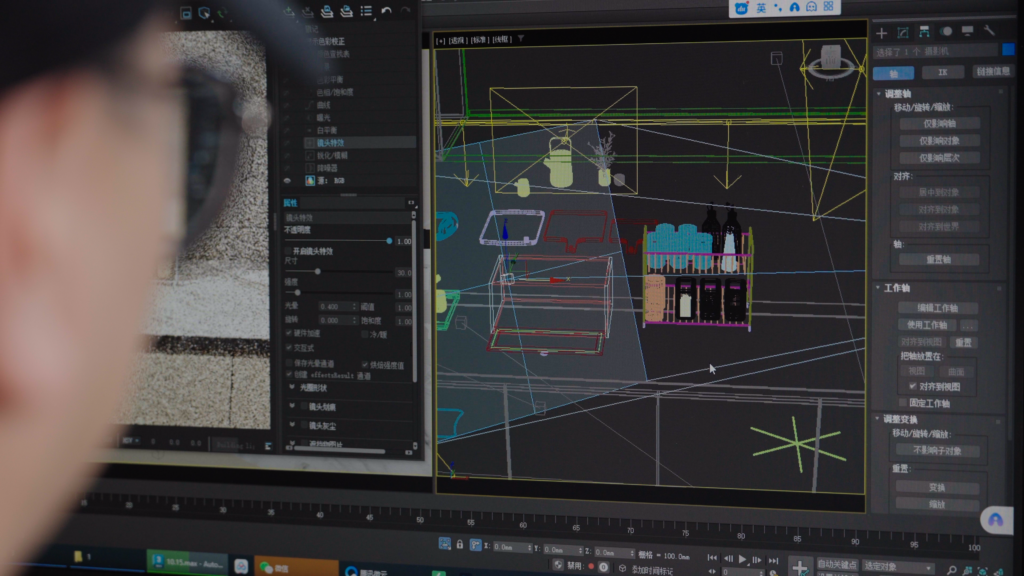

Spanning over 17,000 square meters, our state-of-the-art factory is designed to seamlessly integrate every stage of production. With three specialized buildings, each dedicated to specific functions —including raw material processing, product prototyping, mass production, and packaging—we ensure efficiency, precision, and quality at every step.

Advanced Equipment and Rigorous Process

Our facility is equipped with cutting-edge machinery and adheres to the highest international standards, earning EU-certified export credentials. This recognition underscores our commitment to excellence and sustainability in manufacturing. Moreover, we are proud to be the sole China region supplier for Kmart, Australia’s largest retail chain, a testament to the trust and reliability we have established with global partners.

Burnishing

In the factory, bamboo products are prepared for grinding. First, the grinding machine is set to an appropriate speed. Then, it starts to grind the bamboo surface along the texture with coarse grinding discs to eliminate roughness. After that, medium and fine grinding discs are used successively to make the surface smoother until the desired finish is achieved.

Drill

Mark the drilling positions on the bamboo products according to the design requirements. After fixing the bamboo products, select a suitable drill bit and install it on the electric drill. Drill slowly perpendicular to the marked points. Pay attention to controlling the force and depth during the process. Clean up the debris after completion.

Drying

After cleaning the bamboo products, place them on a drying rack in a well-ventilated room without direct sunlight, spreading them evenly and avoiding mutual compression. Turn them over at intervals. Store them away after they are completely dry.

Blister

Firstly, clean and dry the bamboo products and place them into a specially made blister mold. Start the blister machine to heat and soften the plastic sheet. By vacuuming, make the plastic closely adhere to the surface of the bamboo products. After cooling and shaping, take them out and the blister process is completed.

Packing

After checking the polished and dried bamboo products for any defects, wrap them with soft paper and place them into custom-made paper boxes. Fill the boxes with foam or sponge for shock absorption. Finally, seal the box and attach a label to ensure they are not damaged during transportation.

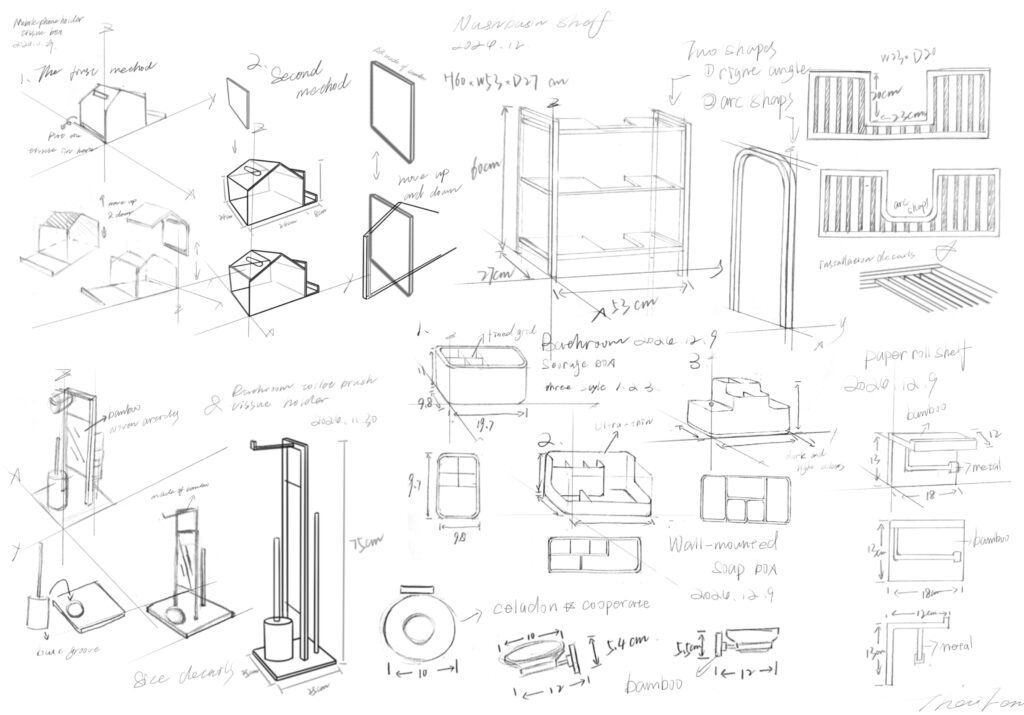

Innovation and Responsibility

At the heart of our enterprise lies a philosophy of innovation and responsibility. By combining advanced technologies with eco-friendly practices, we aim to lead the way in creating sustainable products that meet the evolving demands of the international market. From concept to completion, every product reflects our unwavering commitment to craftsmanship, sustainability, and global excellence.